Epoxy Tests & Comparison

There is much conventional wisdom about how strong adhesives are and which ones are strongest for rocketry use, but little hard evidence. That two-part adhesives such as epoxies are the best is pretty unequivocal, at least for high-power rocketry. But, is hobby shop epoxy strong enough, or do you need to go to "professional" epoxy systems? What techniques produce the strongest bonds?

It has been pointed out that epoxy systems (among many other adhesive products) are rated using a standard system. ASTM International test products submitted by manufacturers using standardized procedures. These results are available from the manufacturers of the products tested. It is important to point out that the testing described here is in no way an attempt to reproduce standardized testing. Our goal is to test typical HPR materials and adhesives using typical best practices for the hobby.

Two tests were perfomed, both "lap-shear" tests of strips bonded together; test 1 with G-10 and (unreinforced) plywood and test 2 with fiberglass-reinforced plywood. To cut to the chase, here are the five conclusions which I drew from these two tests:

- The adhesive and/or wood used in plywood is weaker than the epoxies, therefore which epoxy you use is not very significant when bonding plywood.

- Professional epoxy systems are substantially stronger than Bob Smith epoxy for bonding G-10.

- Aeropoxy ES6209 is the strongest for this kind of bonding, for both G-10 and plywood.

- Laminating plywood with fiberglass dramatically improves its strength, and the strength of a bond to it.

- West System and Aeropoxy products are both good choices for this application, with Aeropoxy having the edge in strength.

The rest of this page describes the test goals and process and presents the full results. Note that these tests were done in 2002 and have informed my epoxy choice ever since (AeroPoxy ES6209 is my go-to for general bonding).

Test Goals

Well, it sounds like we need to do some real testing! Since I'm concentrating on high-power rockets, I am only considering epoxies. (I would encourage someone to do a model rocket version using lightweight materials.) I'm also going to use typical HPR materials such as plywood and G-10 phenolic.

| a | Bob Smith (Hobby shop) epoxy is the most commonly used epoxy in modeling since it is widely available and easy to use. It mixes one-to-one (resin to hardener), which requires fillers in the hardener which supposedly make it weaker. Shown are the 5-minute ("quick") and 30-minute ("slow") versions. |  |

| b | West System epoxy products are widely used because of the convenience and easy availability. If you buy into the system, pumps and all, you have a versatile and easy to use system. Unlike hobby shop epoxy, West System is very thin, perfect for fiberglassing. To thicken it, you can use a variety of powdered additives, each of which has its own uses. |  |

| c | Aeropoxy products were designed for the small airplane industry. The products have higher mechanical properties than West System (including slightly higher temperature resistance). They are less convenient that other epoxy systems to use, but may provide better strength. PR2032 is primarily a laminating adhesive, which can also be used for structural applications. ES6209 is primarily a structural adhesive. |  |

This gives us four products to try:

- Bob Smith epoxy (30 minute)

- West System 105 (206 hardener)

- Aeropoxy PR2032 (PH3660 hardener)

- Aeropoxy ES6209 (parts A and B)

This testing languished for a long time because I had no good way to accurately test the breaking strength of samples. The late Drake Damerau posted on R.M.R. about doing real testing and we managed to hook up. The actual testing was done by Drake using machinery at his job (Scranton Army Ammunition Plant).

Methodological notes:

- All epoxy products were purchased at retail by me from typical hobby suppliers: Bob Smith from a local hobby shop, West System from a local West Marine store, Aeropoxy PR2032 from Aircraft Spruce and Specialty Supply and Aeropoxy ES6209 from Shadow Composites.

- Material blanks in a single test series are from identical sources and times. The plywood blanks for test 1 were supplied by Loc/Precision and the G-10 by Giant Leap Rocketry.

- The samples were all prepared by me using the same techniques and in the same location (the hobby room inside my house).

- The test strips were cut from the interior of the larger test blanks so that no edges of the glue-ups were included.

That said, this is fundamentally hand work (as we do when building rockets), which results in variation between the samples. The standard deviations for the sample sets quantify that variation.

Test 1: G-10 and Plywood

Most uses of epoxy are for general bonding so that's what we'll test.

For the first test, I chose heavy-weight G-10 and 3/8" plywood as representative of high-power

construction.

This gives us two kinds of materials to try:

Most uses of epoxy are for general bonding so that's what we'll test.

For the first test, I chose heavy-weight G-10 and 3/8" plywood as representative of high-power

construction.

This gives us two kinds of materials to try:

- G-10 (.091")

- 3/8" 5-ply birch plywood

Note that no fillers were used with any epoxy. The Bob Smith and Aeropoxy ES6209 are naturally thicker than the laminating epoxies (West System and Aeropoxy PR2032). The ES6209 is so viscous that it's difficult to measure small quantities accurately.

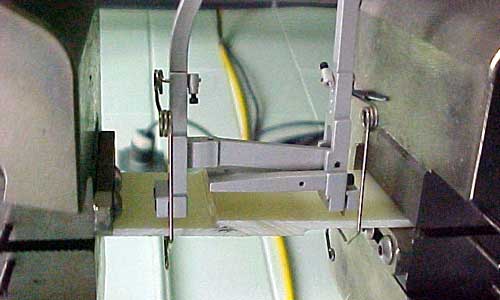

|

The detail on the right shows how the G-10 blanks were sanded along the lamination area

to improve bonding.

The area of overlap was roughed up with 60 grit sandpaper with strokes going in both

directions.

(Note how the area of overlap is marked with lines on all blanks.)

Below you can see how the samples were bonded, using spring clamps to apply uniform pressure. |

|

|

|

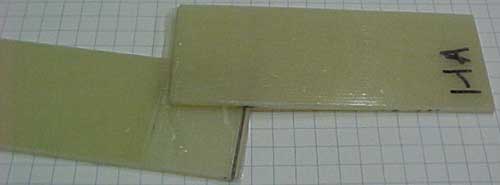

| The detail on the right shows the samples after the bonded blanks were cut into uniform strips. (Each blank yielded three 1½" wide strips.) |  |

The samples were then sent to Drake for testing in his machinery. (More information and raw results are available on his site.)

In the picture above, you can see the first G-10 sample in the test machine. The ends of the sample are pulled apart (stretched) until the joint breaks. The machine measures the maximum force (in pounds) applied before breaking, which is the measurement reported as Strength below.

Comments from Drake after testing:

"The primary mode of failure in the plywood tests was delamination of the wood. Some of the epoxies did penetrate deeper into the wood, but the test results hinged on the strength of the wood. In every case, they broke at the joint and they all delaminated at the joint surface (not the core).

"The G-10 results were quite different in that the epoxy appeared to dissolve the G-10 and re-solidify. The Bob Smith had very little ability to dissolve the material, while the other two seemed to be 'hotter' and dissolved the material considerably."

| Sample | Material | Epoxy | Strength # | Average |

|---|---|---|---|---|

| 1-1A | G-10 | Bob Smith | 503.131 | 484.5 (SD 30) |

| 1-1B | G-10 | Bob Smith | 441.942 | |

| 1-1C | G-10 | Bob Smith | 508.475 | |

| 1-1D | plywood | Bob Smith | 1016.953 | 1101.7 (SD 169) |

| 1-1E | plywood | Bob Smith | 1337.724 | |

| 1-1F | plywood | Bob Smith | 950.419 | |

| 1-2A | G-10 | West System | 2379.331 | 2346.5 (SD 24) |

| 1-2B | G-10 | West System | 2337.961 | |

| 1-2C | G-10 | West System | 2322.104 | |

| 1-2D | plywood | West System | 986.271 | 1064.1 (SD 78) |

| 1-2E | plywood | West System | 1034.878 | |

| 1-2F | plywood | West System | 1171.047 | |

| 1-3A | G-10 | Aeropoxy PR2032 | 1937.386 | 1879.1 (SD 158) |

| 1-3B | G-10 | Aeropoxy PR2032 | 2037.357 | |

| 1-3C | G-10 | Aeropoxy PR2032 | 1662.633 | |

| 1-3D | plywood | Aeropoxy PR2032 | 1263.091 | 1022.0 (SD 181) |

| 1-3E | plywood | Aeropoxy PR2032 | 977.309 | |

| 1-3F | plywood | Aeropoxy PR2032 | 825.455 | |

| 1-4A | G-10 | Aeropoxy ES6209 | 2574.789 | 2399.3 (SD 137) |

| 1-4B | G-10 | Aeropoxy ES6209 | 2383.984 | |

| 1-4C | G-10 | Aeropoxy ES6209 | 2239.198 | |

| 1-4D | plywood | Aeropoxy ES6209 | 2047.869 | 2071.6 (SD 208) |

| 1-4E | plywood | Aeropoxy ES6209 | 1829.139 | |

| 1-4F | plywood | Aeropoxy ES6209 | 2337.961 |

My hypothesis was that there would be little or no difference between epoxies. However, it's very obvious that the strength difference is pronounced. The plywood samples are very interesting. There is no significant difference between the first three epoxies, because all epoxies are stronger than the plywood itself. However, the Aeropoxy ES6209 plywood samples required twice the breaking force. Drake says:

"I can't explain for sure the difference between the [Aeropoxy ES6209] samples and the other plywood samples. There seems to be less delaminating of the plywood and more shearing of the epoxy on these. Otherwise, they are the same. Unfortunately, the differences are generally too subtle to document with a photograph."

| Epoxy | G-10 | Plywood |

|---|---|---|

| Bob Smith | 1 | 1.1 |

| West System | 4.8 | 1.0 |

| Aeropoxy PR2032 | 3.9 | 1 |

| Aeropoxy ES6209 | 5.0 | 2.0 |

The table above summarizes the results in relative terms. The breaking force averages are divided by the lowest value in each category.

Here are some conclusions which arise from this test:

- The adhesive and/or wood used in plywood is weaker than the epoxies, therefore which epoxy you use is not very significant when bonding plywood.

- Professional epoxy systems are substantially stronger than Bob Smith epoxy for bonding G-10.

- Aeropoxy ES6209 is the strongest for this kind of bonding, for both G-10 and plywood.

Of course, one must be careful not to over-generalize from one test. The actual test performed is a "lap-shear" test, which is only one of many types of stress which could be applied to an adhesive bond.

Test 2: Fiberglassed Plywood

The poor performance of the plywood made me want to find out what difference it would make if the plywood had a layer of fiberglass cloth laminated to it. So, we did a small run in the lap-shear series with this third case.

One side of each blank was laminated with 6oz. fiberglass and vacuum bagged on. Then the fiberglass sides were bonded using the same technique as in the other lap-shear tests. One test was done with West System 105/206 for both lamination bond and the other was done with Aeropoxy PR2032 to laminate the fiberglass and ES6209 to bond the pieces. The laminations were allowed to completely cure and were then sanded at the overlap (as with the G-10 blanks).

| |

| |

|

Top: materials for the blanks

(release, breather and 6oz. fiberglass).

Above: plywood with fiberglass laminated (West System on the left and Aeropoxy on the right). Right: samples in the vacuum bag. |

|

The samples were cut into strips and tested in exactly the same was as the other sets of samples in this series.

I suspected that the fiberglass-reinforced blanks would be stronger than plain plywood blanks, but I didn't expect them to be twice as strong. Like the other plywood tests, the plywood failed before the joint, but in this case the fiberglass lamination dramatically increased the strength of the plywood.

Drake comments:

"The fiberglass did break, but only after the core of the wood broke. All the glassed samples broke in the same fashion. Interestingly, none of the glassed samples broke at the joint. They all broke just fore or aft of it. This shows that the joint is stronger than the material."

| Sample | Material | Epoxy | Strength # | Average |

|---|---|---|---|---|

| 1-10A | 'glassed ply | West System | 1909.807 | 1819.9 (SD 67) |

| 1-10B | 'glassed ply | West System | 1800.010 | |

| 1-10C | 'glassed ply | West System | 1749.851 | |

| 1-11A | 'glassed ply | Aeropoxy | 1933.147 | 2044.8 (SD 181) |

| 1-11B | 'glassed ply | Aeropoxy | 2300.385 | |

| 1-11C | 'glassed ply | Aeropoxy | 1900.843 |

Here are some conclusions which arise from this test:

- Laminating it with fiberglass dramatically improves the strength of plywood, and the strength of a bond to it.

- West System and Aeropoxy products are both good choices for this application, with Aeropoxy having the edge in strength.

Alert reader David Tam pointed out that these tests were all done at room temperature and the results may not be applicable at low temperatures.

Other Research

Larry Capps pointed me to a piece of research on bonding wood products using epoxy. Those who are interested in more detail should read it for further info: Structurally Durable Epoxy Bonds to Aircraft Woods.

3M published a paper which is also very interesting. While it's focused on bonding metals, it does have some interesting discussion of the optimal configurations for epoxy joints.